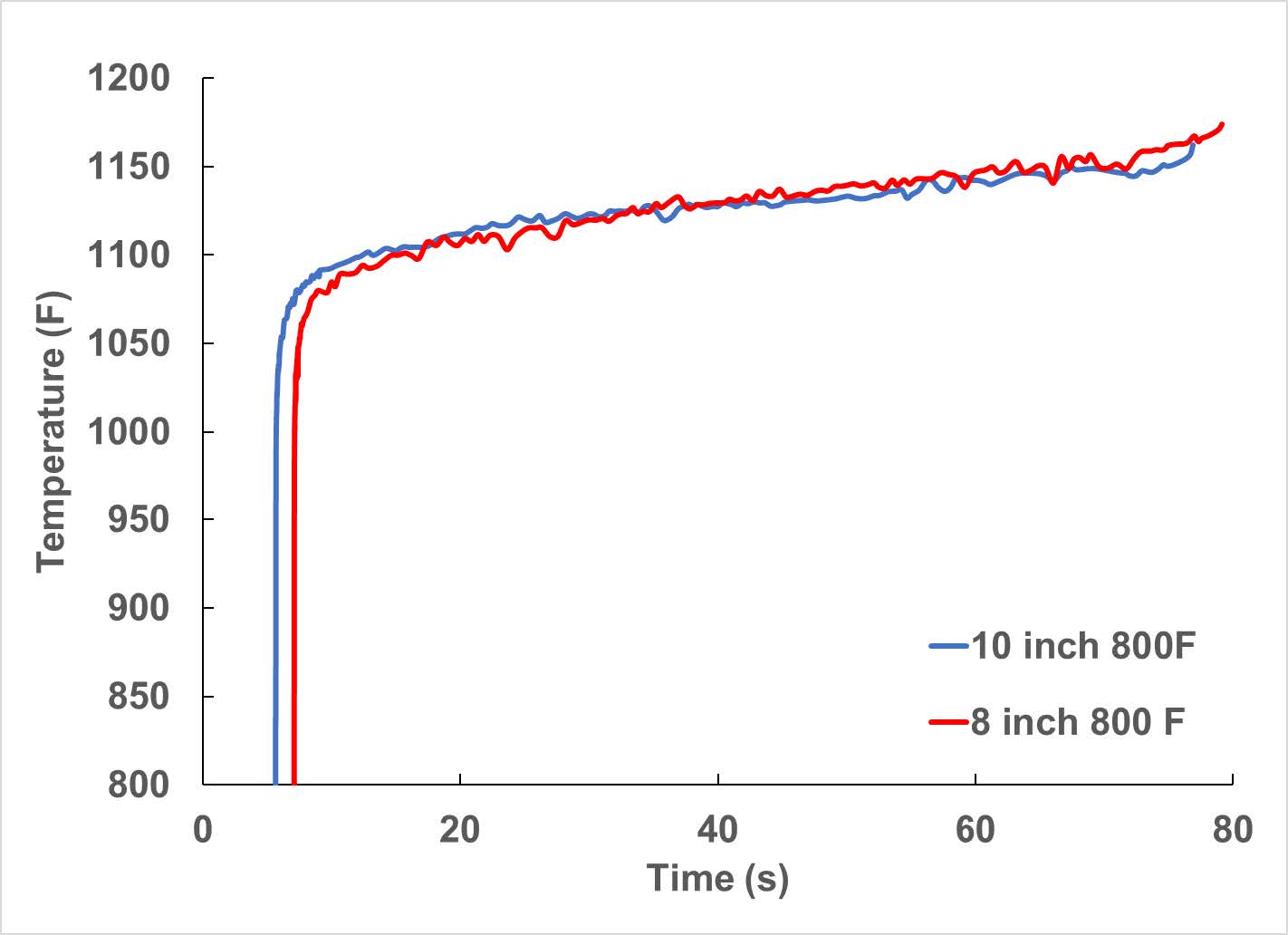

extrusion temperature profile

The article discusses the. 150 205C should not exceed 205C.

Time To Learn About Dynamic Optimization Of Extruder Barrel Temperatures Plastics Technology

This is because that if the length of the belt from increasing its perimeter.

. The hump back temperature profile By Timothy W. Extrusion conditions feed rate 800 g min screw speed 300 rpm twn Aes 4 mm diameter barrel temperature profile 2555120150150C from feed port to die. Another Technique for Controlling Melt Temperature.

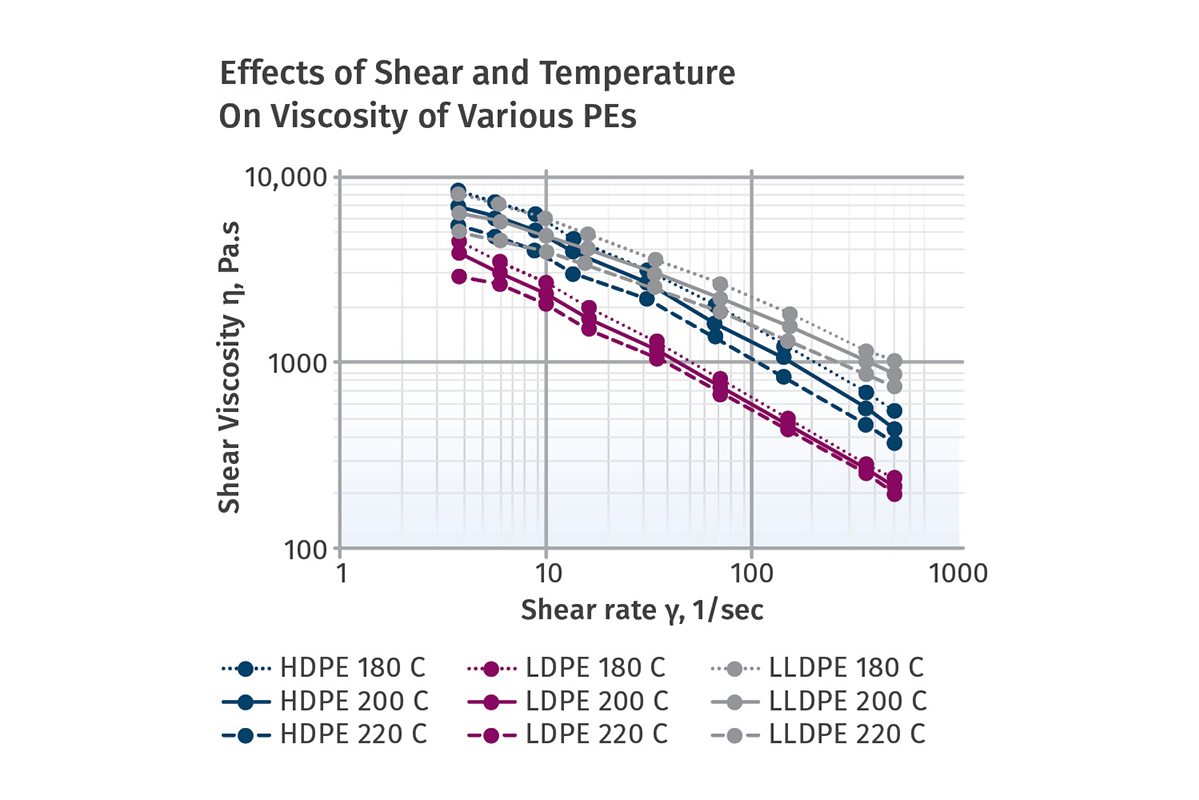

Polyolefins are the most widely used plastics for film extrusion. Extrusion temperature is typically 160180C and the compression ratio is 21 or less. A higher extrusion temperature results in a higher MFR 37 caused by more chain scission.

From Guy and Home 1988 with permission. 36 37 Table 1. Lets say it recommends 450-510 F 230-265 C for a semi-crystalline resin.

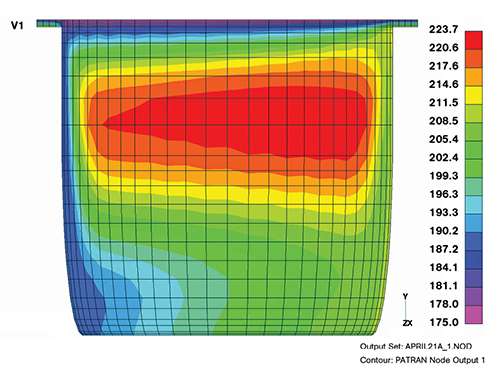

But they can be optimized to reduce. The temperature of the aluminum profile at the outlet of the matrix increases with the perimeter of the girdle matrix. This is done for drying but is helpful.

Single Screw with vacuum grooved feeding section Screw Design. A Du Pont nylon extrusion study noted that exit-melt-pressure fluctuations were seven times more extreme after the temperature of the two rear zones was dropped 50 deg F. This means that drying is not.

Barrier Screw 25 - 30 LD Compression Ratio. 150C at infeed zone to 205C at the die gives highest output. The selected temperature profile was based on typical PP processing parameters.

Profile extrusion refers to the extrusion of polymer melts through dies of cross sections that are neither round annular or rectangular with an aspect ratio WH greater. Reversed Temperature Profile 2 - SPE Extrusion Division 1-0-Wiki EH-V21-2-Ihtml62518 42554 PM SPE Extrusion Division 1-0-Wiki Reversed Temperature Profile 2 Modified on. Usually the resin supplier will provide a range.

Extrusion processes using a barrier-type screw for maximum output and performance need certain finer adjustments of barrel-temperature zone profiles. HDPE will absorb less than 001 water in 24 hours at room temperature. Extrusion may be defined as a process for making a product an extrudate by forcing a material through an orifice or die to form a shape or alternatively the production of finished or semi.

A typical extrusion line for processing flexible Vinyl will contain the following equipment. Length to diameter ratio should be 24 to 1. Pick something near the center in this case 485 F 250.

More often than not extrusion operators. A Guide To Polyolefin Film Extrusion contains general information concerning materials methods and equipment for. Extrusion coating where high melt temperature means lower viscosity and better adhesion to paper and other substrates.

Die correction for the profiles for accommodating shrinkage and swelling. Sizes include 15 to 45 inch machines. The melt is extruded through a circular die to produce a highly puffed rope which is cut to the desired size by a revolving blade.

Flight widths are almost always designed at 10 of the screw diameter. PP - Polypropylene Extruder. Womer Resin Type Melt Index Density Melt Temp Target - ºF Z-N LLDPE 10 0918 400 to 430.

Some instructions for extruding HDPE.

Barrel Temperature Profiles In C Download Table

Extruder Barrel Temperature Settings Temperature Settings Set Download Table

Example Of A Temperature Profile Of Plastic Extrusion Download Scientific Diagram

Extruder Barrel Temperature Settings Temperature Settings Set Download Table

Applied Sciences Free Full Text Effects Of Solid Die Types In Complex And Large Scale Aluminum Profile Extrusion Html

Extruder Barrel Temperature Settings Download Table

Article Extrusion Productivity Part I Billet Geometry Light Metal Age Magazine

Extrusion Ratio An Overview Sciencedirect Topics

What Is Extrusion Plastic Extrusion Process Elastron Tpe

Understanding Viscosity In Extrusion Plastics Technology

Schematic Illustration Of The Extrusion Line And The Temperature Of The Download Scientific Diagram

The Role Of Screw Design In Efficient Extrusion Of Medical Devices Plastics Technology

Bc 60 Extruder Barrel Arrangement And Dimensions Download Scientific Diagram

0 Response to "extrusion temperature profile"

Post a Comment